Shop by Category

- CVD Diamond Tools

- Drills Taps Thread Tools

- EDM Filters

- EDM Graphite

- EDM Oils & Fluids

- EDM Tooling

- EDM Tubing

- EDM Wire

- General Purpose Tools

- Hard Milling Tools

- High speed mills

- JJ Tools

- Micro Welders

- Millstar

- Mold Components

- Mold Polishing Supplies

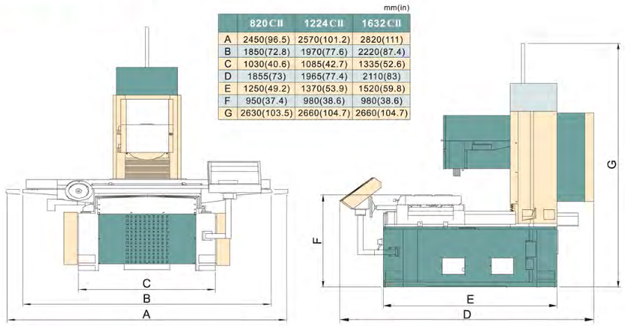

- New EDMs

- Slide Mold Solutions

- specials

- Stainless Steel Titanium Tools

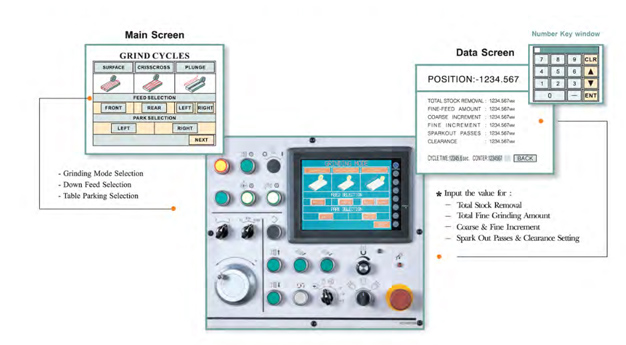

- Surface Grinders

- USED EDM INVENTORY

- Wire EDM Wear Parts